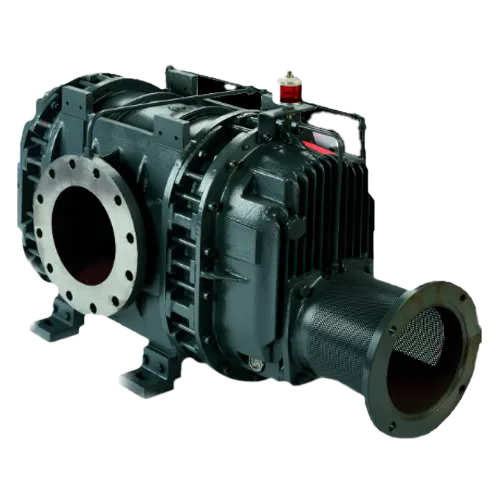

Vacuum Pumps – Industrial Vacuum Solutions for Diverse Applications

Vacuum Pumps are essential equipment used to remove gases from sealed systems and create controlled vacuum environments for industrial, scientific, and manufacturing processes. From general industrial applications to high-precision and ultra-high vacuum requirements, vacuum pumps play a critical role in ensuring process efficiency, product quality, and operational reliability. Ultrahivac offers a comprehensive range of vacuum pumps including oil-sealed, dry, and high-vacuum technologies, engineered to meet the needs of diverse industries across India.

Key Features & Benefits

Wide range of vacuum technologies for low, medium, high, and ultra-high vacuum

Reliable performance for continuous industrial operation

Options for oil-sealed and oil-free applications

Designed for energy efficiency and long service life

Suitable for general, industrial, and precision vacuum requirements

Products

Available Types of Vacuum Pumps

Benefits

Reasons To Choose Our Vacuum Pumps

Industries

Applications of Vacuum Pumps

Information

How It Works and Technical Advantages

Gas Intake and Capture

Compression Mechanism

Gas Transfer and Movement

Exhaust and Discharge

Vacuum Level Control

System Stabilisation and Operation

FAQs for Vacuum Pumps

Vacuum pumps are used to create controlled vacuum environments for industrial, scientific, and manufacturing processes.

The best pump depends on the application, required vacuum level, and process conditions.

Yes, many industrial vacuum pumps are designed for continuous duty cycles.

Vacuum pumps are widely used in semiconductors, chemicals, pharmaceuticals, aerospace, automotive, and manufacturing industries.

Selection depends on vacuum range, gas type, cleanliness requirements, and system configuration.