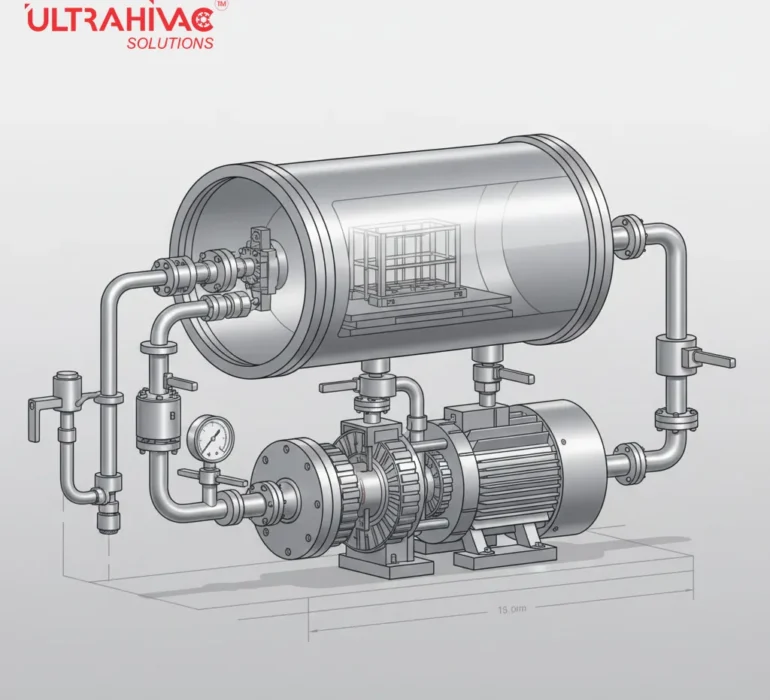

When vacuum systems are discussed, most attention naturally goes to vacuum pumps. While pumps are important, they are only one part of the equation. In real-world industrial environments, system performance is defined not by a single piece of equipment but by how well all vacuum components work together.

Vacuum components are the silent enablers. They don’t generate vacuum themselves but without them, achieving and maintaining stable pressure would be impossible.

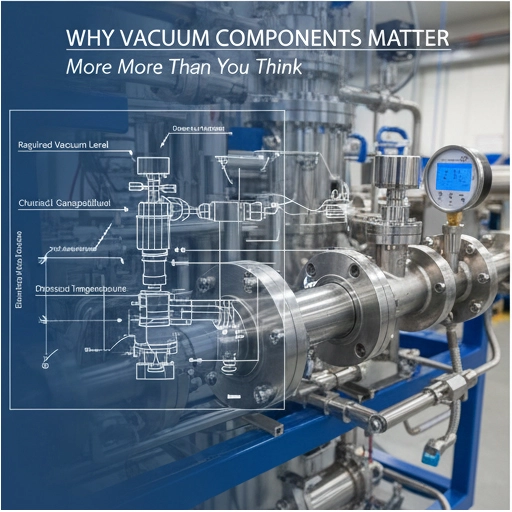

Why Vacuum Components Matter More Than You Think

In controlled vacuum environments, even the smallest inconsistency can lead to major process issues. A poorly sealed joint, an incompatible valve or a low-quality fitting can introduce leaks, contamination or pressure instability.

Vacuum components ensure:

Leak-tight operation

Controlled gas flow

System safety and isolation

Accurate monitoring and measurement

In short, they convert theoretical vacuum performance into real, repeatable results.

The Role of Integration

A vacuum system is not assembled randomly. Each component must be selected based on:

Required vacuum level

Process temperature

Chemical compatibility

Maintenance accessibility

Ignoring integration often leads to systems that work briefly, then degrade over time.

Reliability Comes From Design Discipline

Well-designed vacuum systems don’t demand constant attention. They operate quietly in the background, supporting critical processes day after day. This reliability is built at the component level long before the system is switched on.

Closing Perspective

Vacuum components may not be glamorous, but they are fundamental. Investing time in understanding them leads to better system design, fewer failures, and longer operational life.