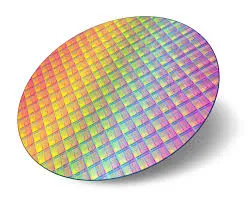

Silicon Wafers are ultra-flat, high-purity crystalline silicon substrates used as the foundation for semiconductor devices, microelectronics, sensors, and advanced thin-film applications. Manufactured with strict control over crystal orientation, thickness, and surface finish, silicon wafers play a critical role in determining device performance, yield, and reliability. They are widely used in semiconductor fabrication, research laboratories, coating processes, and advanced material studies. Ultrahivac supplies high-quality silicon wafers suitable for research, pilot production, and industrial applications across India.

Key Features & Benefits

High-purity crystalline silicon material

Excellent surface flatness and uniform thickness

Available in multiple orientations and resistivity ranges

Suitable for thin-film deposition and device fabrication

Compatible with high and ultra-high vacuum processes

Benefits

Reasons to Choose Our Silicon Wafers

Industries

Applications of Silicon Wafers

Information

How It Works and Technical Advantages

Crystal Growth

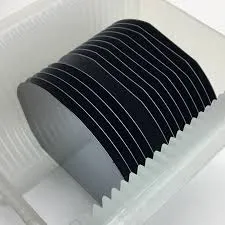

Wafer Slicing

Surface Polishing

Cleaning and Preparation

Substrate Utilisation

Continuous Process Compatibility

FAQs for Silicon Wafers

They are used as substrates for semiconductor devices and thin-film applications.

Yes, they are compatible with high and ultra-high vacuum systems.

Yes, common orientations include ⟨100⟩, ⟨110⟩, and ⟨111⟩.

Yes, they are widely used as substrates in PVD and CVD processes.

Yes, they are designed for consistent performance in research and industry.