Vacuum Coating Materials – High-Purity Materials for PVD, CVD, and Thin-Film Deposition Processes

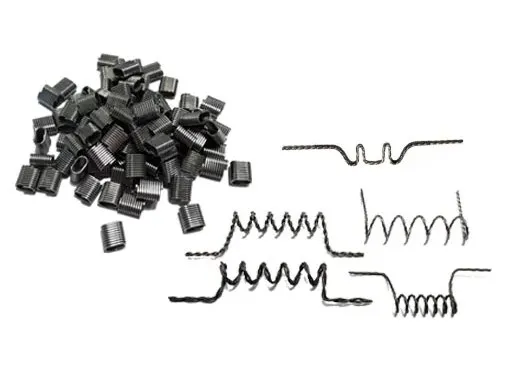

Vacuum Coating Materials are high-purity materials used as source materials in vacuum deposition processes such as Physical Vapour Deposition (PVD) and Chemical Vapour Deposition (CVD). These materials are evaporated or sputtered under vacuum to form thin, uniform coatings on substrates. Available in various forms including pellets, granules, wires, rods, and sputtering targets, vacuum coating materials play a critical role in determining coating quality, adhesion, and performance. Ultrahivac supplies high-quality vacuum coating materials suitable for research, industrial, and production coating applications across India.

Key Features & Benefits

High purity for consistent and defect-free coatings

Available in multiple material types and forms

Supports uniform and repeatable thin-film deposition

Compatible with PVD and CVD processes

Suitable for research and industrial coating systems

Benefits

Reasons to Choose Our Vacuum Coating Materials

Industries

Applications of Vacuum Coating Materials

Information

How It Works and Technical Advantages

Material Preparation

Chamber Loading

Vacuum Environment Creation

Material Vaporisation

Thin-Film Formation

Continuous Coating Operation

FAQs for Vacuum Coating Materials

They are used as source materials for thin-film deposition in vacuum systems.

They are used in PVD, CVD, evaporation, and sputtering processes.

Yes, material purity and form directly impact coating performance.

Yes, they are available as pellets, granules, wires, rods, and targets.

Yes, they are designed for both research and industrial production environments.