Vacuum Chambers – Precision-Engineered Enclosures for Controlled Vacuum Environments

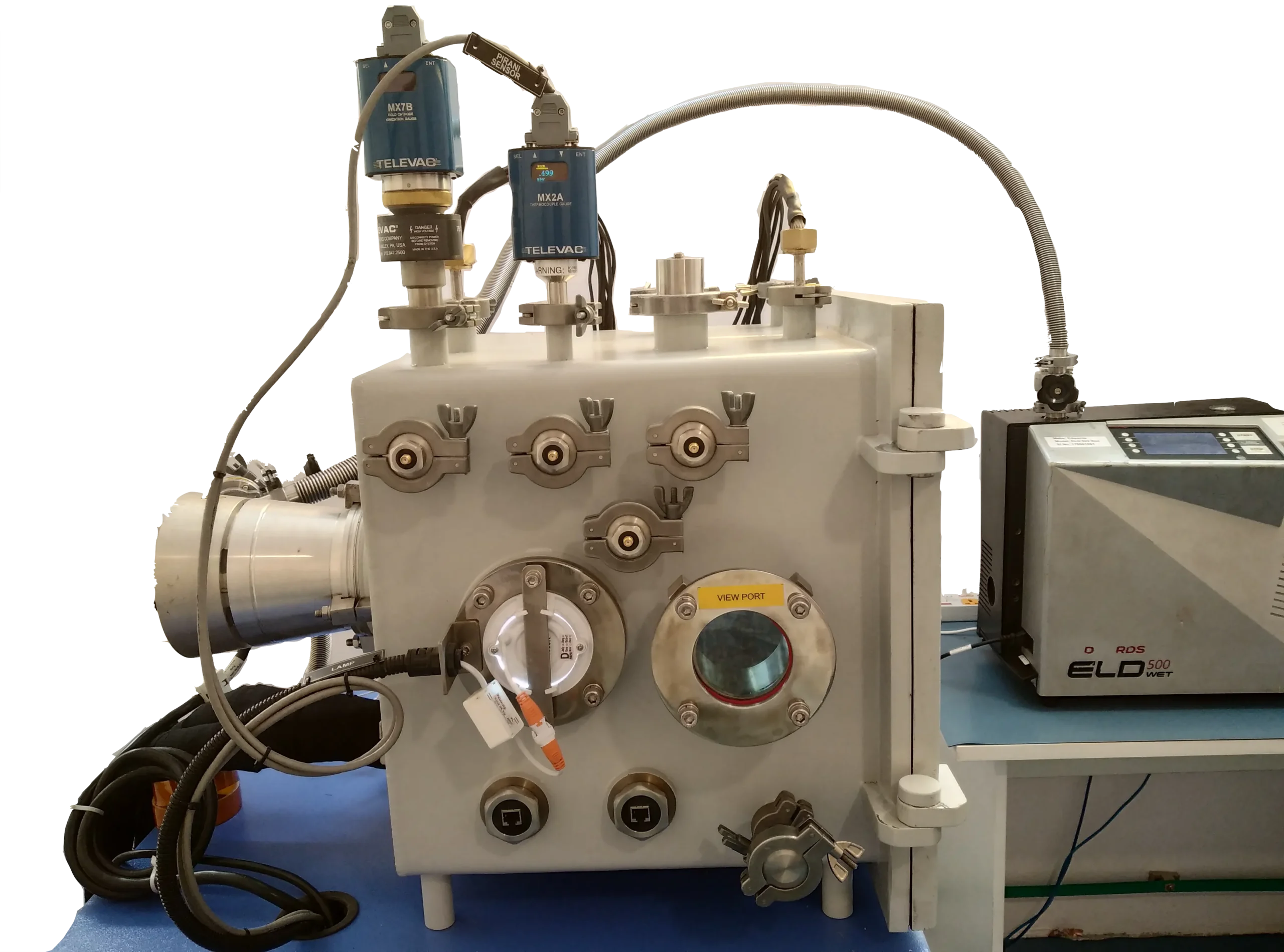

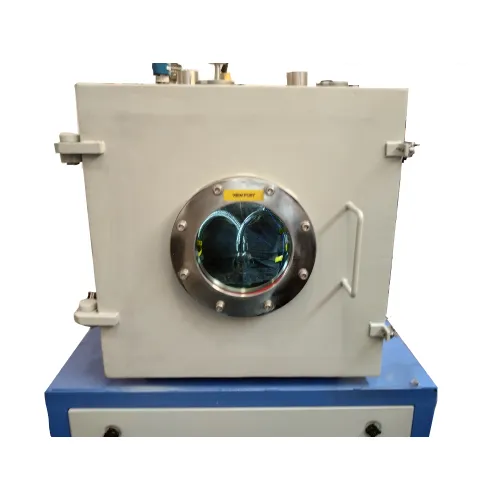

Vacuum Chambers are sealed enclosures designed to create and maintain controlled vacuum environments for testing, processing, research, and manufacturing applications. Engineered to withstand external atmospheric pressure, vacuum chambers are critical components in vacuum systems used across scientific, industrial, and high-technology processes. Available in various shapes, sizes, and materials, vacuum chambers can be customised to suit specific applications, vacuum levels, and integration requirements. Ultrahivac supplies robust vacuum chambers engineered for reliability, precision, and long service life across industries in India.

Key Features & Benefits

Rigid, leak-tight construction for stable vacuum environments

Available in multiple materials such as stainless steel and aluminium

Customisable ports, flanges, and access options

Designed for low, high, and ultra-high vacuum applications

Suitable for laboratory and industrial use

Benefits

Reasons To Choose Our Vacuum Chambers

Industries

Applications of Vacuum Chambers

Information

How It Works and Technical Advantages

Sealed Chamber Construction

Vacuum Pump Connection

Pressure Reduction

Vacuum Stability Maintenance

Access and Instrumentation Ports

Continuous Vacuum Operation

FAQs for Vacuum Chambers

They are used to create controlled vacuum environments for testing, processing, and research.

Yes, they can be designed with custom sizes, ports, and configurations.

Common materials include stainless steel and aluminium, depending on application needs.

Yes, designs can be tailored for high and ultra-high vacuum applications.

Yes, they are designed for continuous industrial and laboratory operation.