Vacuum technology plays a vital role in science and industry, spanning a wide range of pressure levels, from Rough Vacuum to Ultra-High Vacuum (UHV). Each vacuum level serves unique purposes and requires specialized equipment and expertise to achieve optimal conditions. At Ultrahigh Vacuum Solutions LLP, we offer tailored solutions for every vacuum regime. This guide explains the fundamentals of rough vacuum, high vacuum, and ultra-high vacuum, helping you understand their differences, physics, and applications.

What is Rough Vacuum?

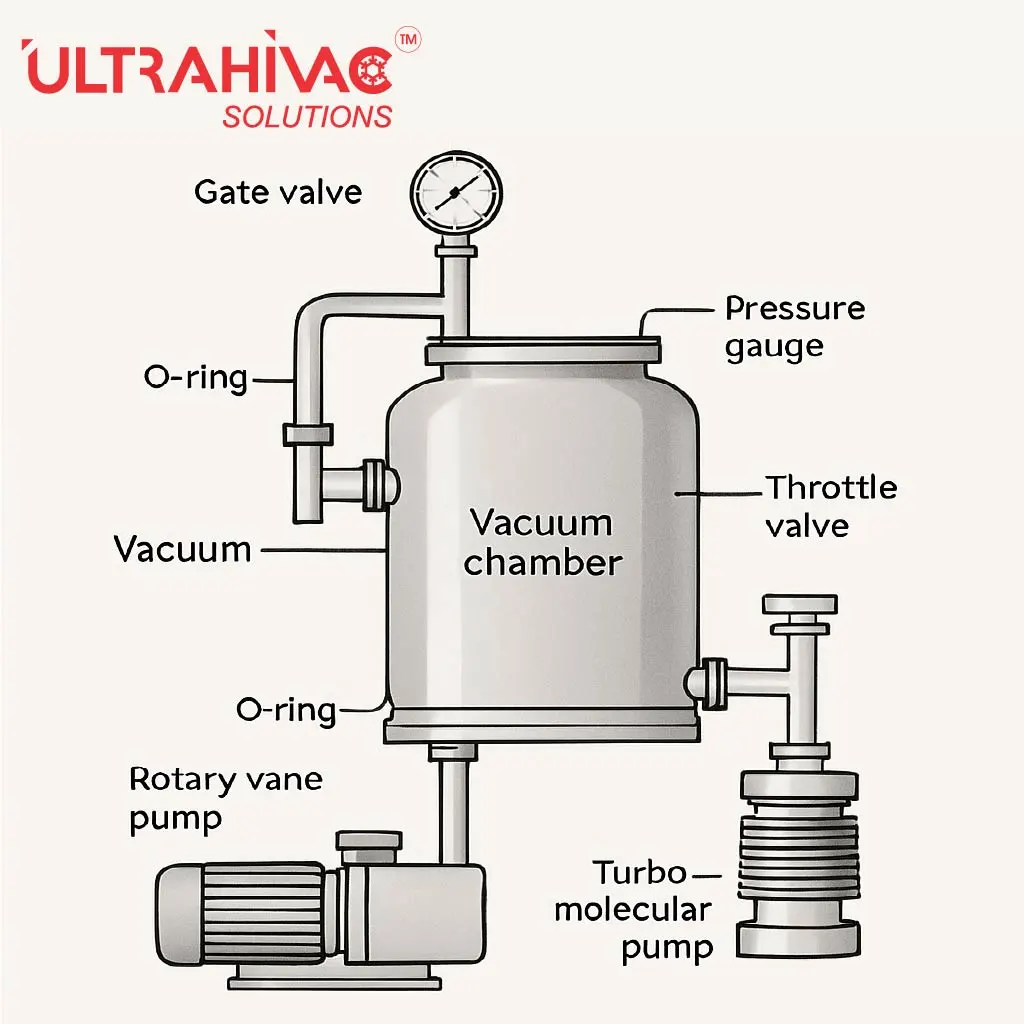

Rough Vacuum covers pressures from atmospheric pressure down to about 10-3 torr. It is the starting point for most vacuum systems and is crucial for processes like vacuum packaging, freeze drying, and initial pump-down stages. Rough vacuum pumps, such as rotary vane or scroll pumps, remove the bulk of air to reach these intermediate pressure levels.

Understanding High Vacuum (HV)

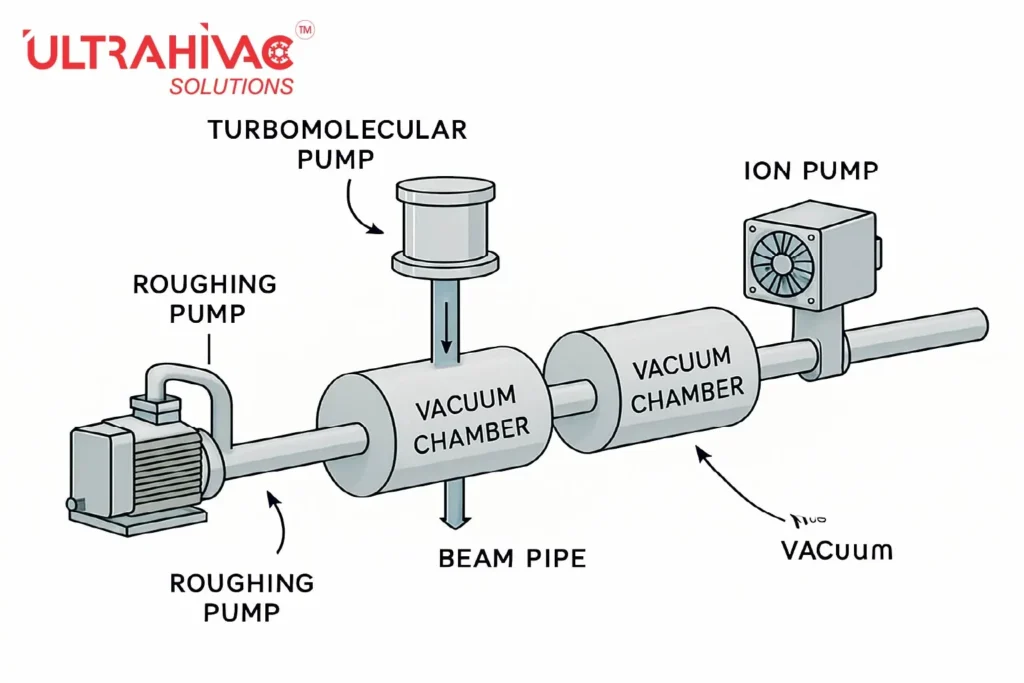

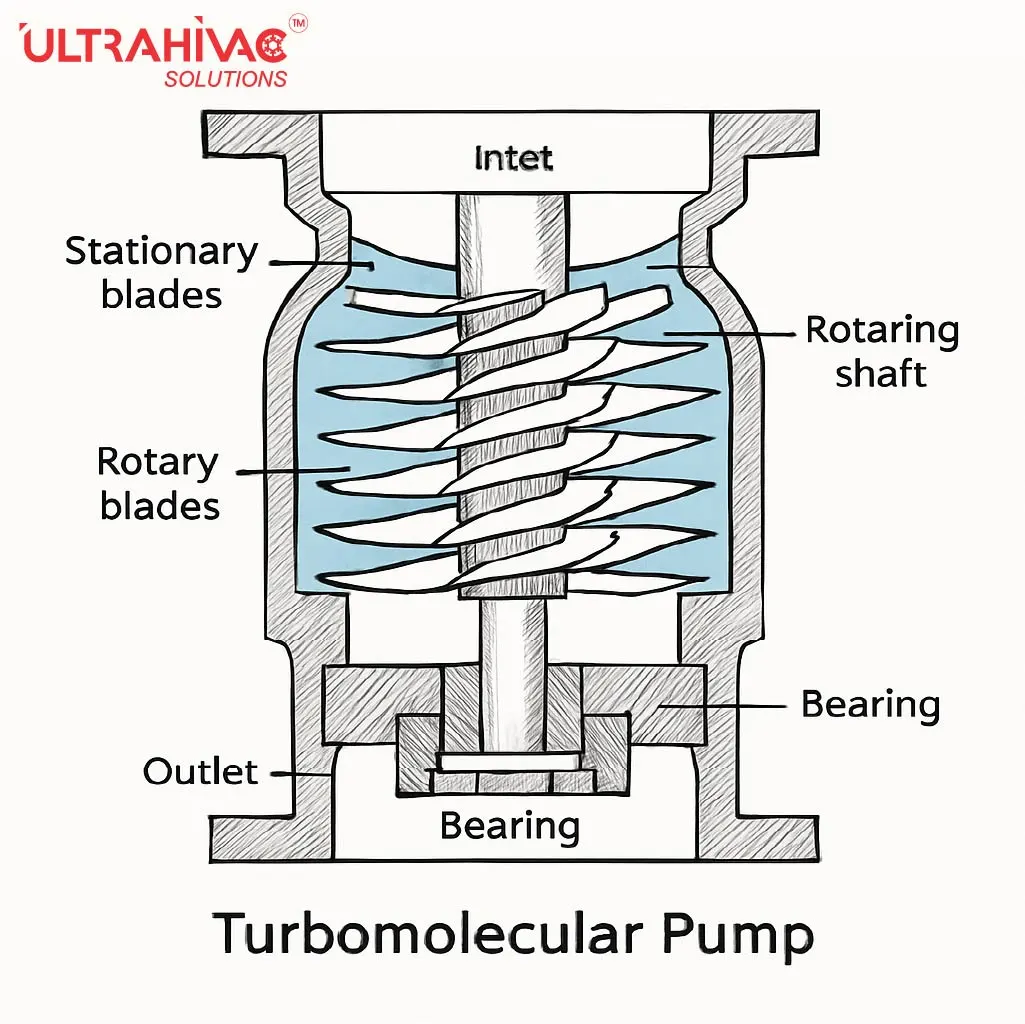

High Vacuum operates between 10−3 torr down to about 10-6 torr. At these levels, gas molecules begin to behave differently, transitioning into molecular flow where collisions between molecules are less frequent. High vacuum is commonly found in electron microscopy, vacuum coating, and many analytical instruments. Pumps like turbomolecular pumps are employed to maintain and achieve these pressure levels.

What is Ultra-High Vacuum (UHV)?

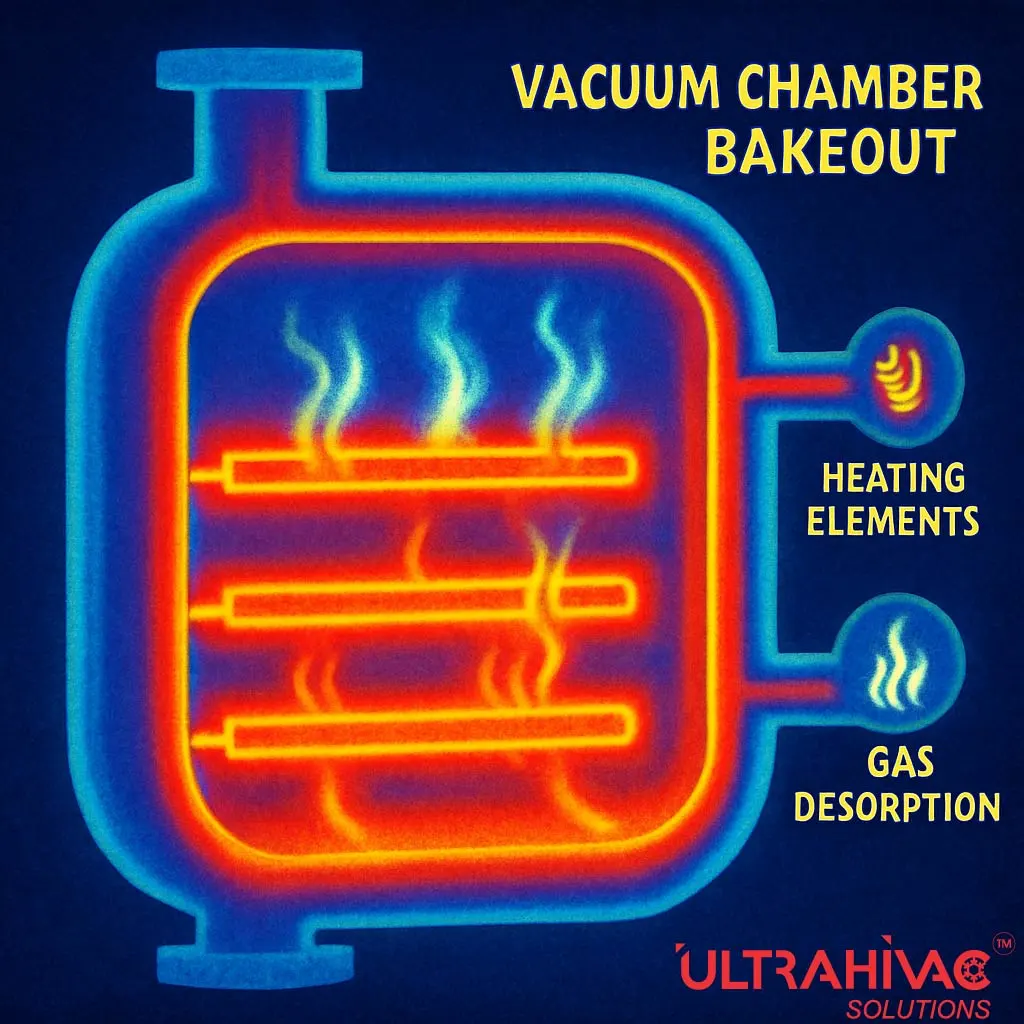

Ultra-High Vacuum achieves pressures below 10-7 torr, representing some of the cleanest vacuum environments possible. At UHV, gas molecules almost never collide with each other, traveling long distances before interacting with chamber surfaces. Specialized design features such as metal seals, bake out procedures and ion or cryogenic pumps are required to achieve UHV conditions. Applications include surface science, particle accelerators, semiconductor manufacturing, and quantum physics experiments.

The Science of Vacuum Flow Regimes

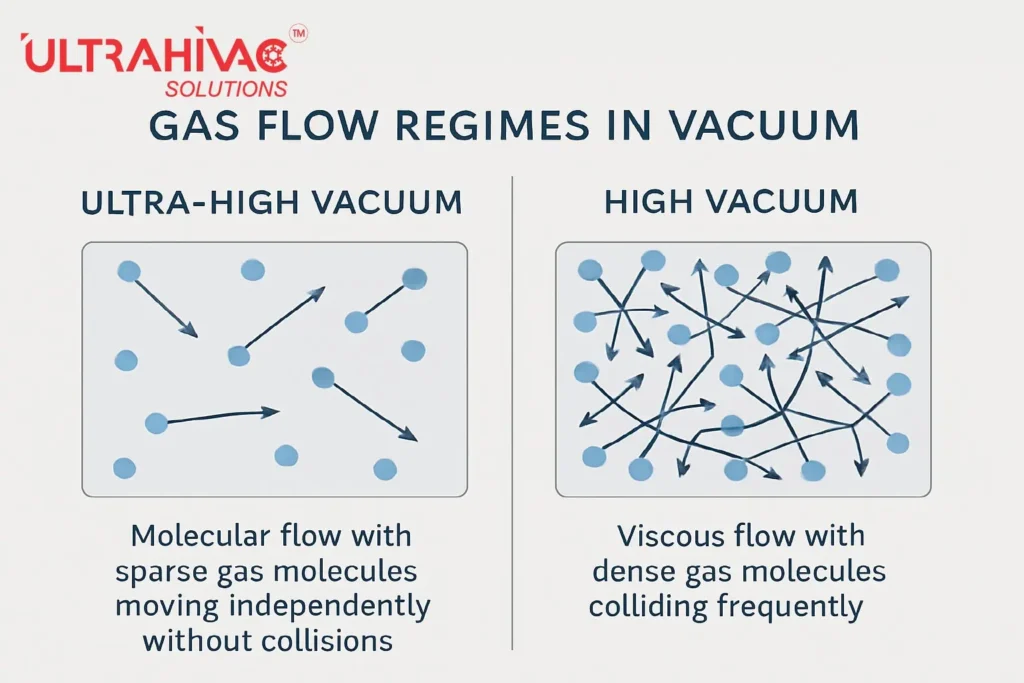

- Rough Vacuum: Viscous flow dominates; gas molecules collide frequently, and pump efficiency depends on bulk gas removal.

- High Vacuum: Transitional to molecular flow; molecules begin to travel independently, reducing gas collision frequency.

- Ultra-High Vacuum: Molecular flow dominates; gas molecules rarely collide, requiring extreme care in material choice and system design.

Why Choose Ultrahigh Vacuum Solution LLP?

At Ultrahigh Vacuum Solution LLP, we understand the unique challenges posed by each vacuum regime. Our expert team provides:

- Comprehensive vacuum solutions covering rough, high and ultra-high vacuum.

- Advanced pumps, components, and custom engineering tailored to your application.

- Expertise in minimizing contamination, outgassing and system leakage.

- Support across industries including manufacturing, research laboratories and high-tech engineering.

- Our team analyses and understands the requirements of the customers before proceeding with the solutions.

- Wide range of vacuum products, Services and custom solutions based on the customer needs.

Applications Across Vacuum Ranges

| Vacuum Range | Typical Pressure Range (torr) | Applications |

| Rough Vacuum | Atmospheric to 10-3 | Vacuum packaging, Pick and Place, Vacuum Thermo Forming, freeze drying, initial pump-down, Vacuum Cooling, Vacuum Drying, Vacuum impregnation, Solar and Wind Energy Etc., |

| High Vacuum | 10-3 to 10-6 | Electron microscopy, vacuum coating, analytical instruments, Vacuum Furnace, Vacuum Metallurgy, Research and Development , Ion Implanters, |

| Ultra-High Vacuum | Below 10-7 | Surface science, Particle Accelerators, semiconductor Processes, |

Partner with Ultrahigh Vacuum Solution LLP

Choosing the right vacuum partner impacts your system’s performance and reliability. With decades of experience, cutting-edge technology, and customer-focused solutions, Ultrahigh Vacuum Solution LLP is your trusted partner for all vacuum needs.

Contact us today to explore how we can help design and implement the perfect vacuum environment for your application.