Sputtering Targets – High-Purity Targets for Precision Thin-Film Deposition Processes

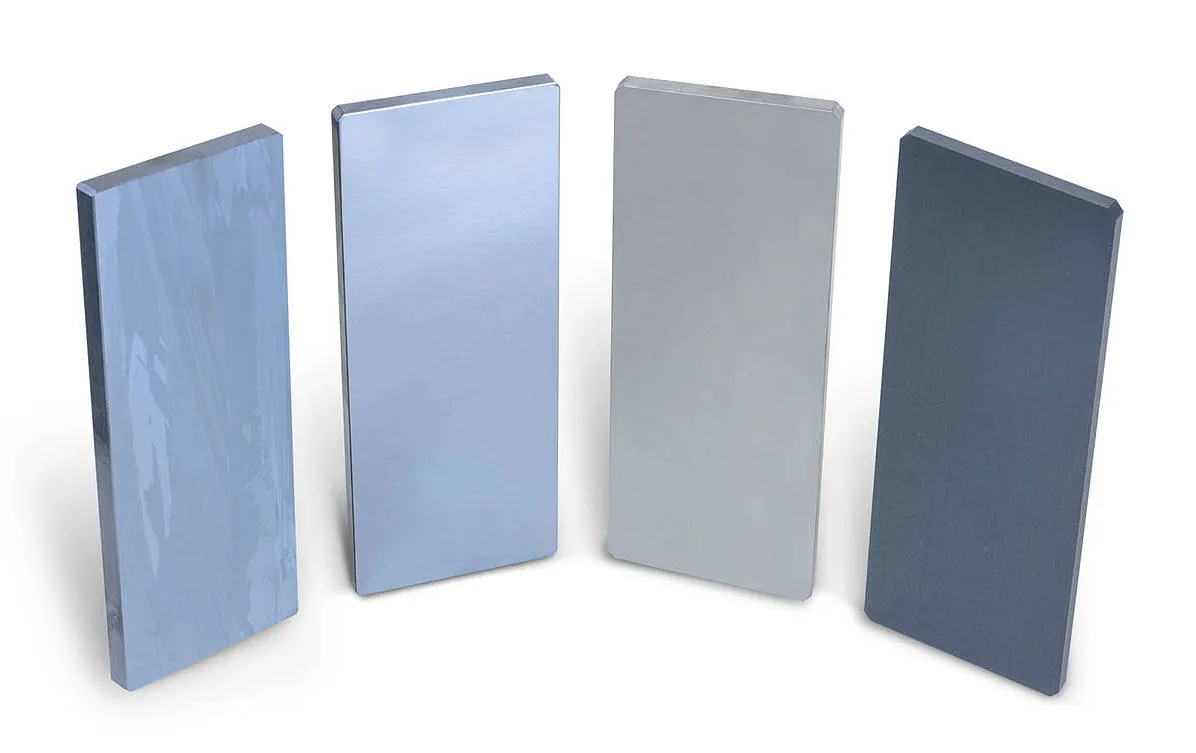

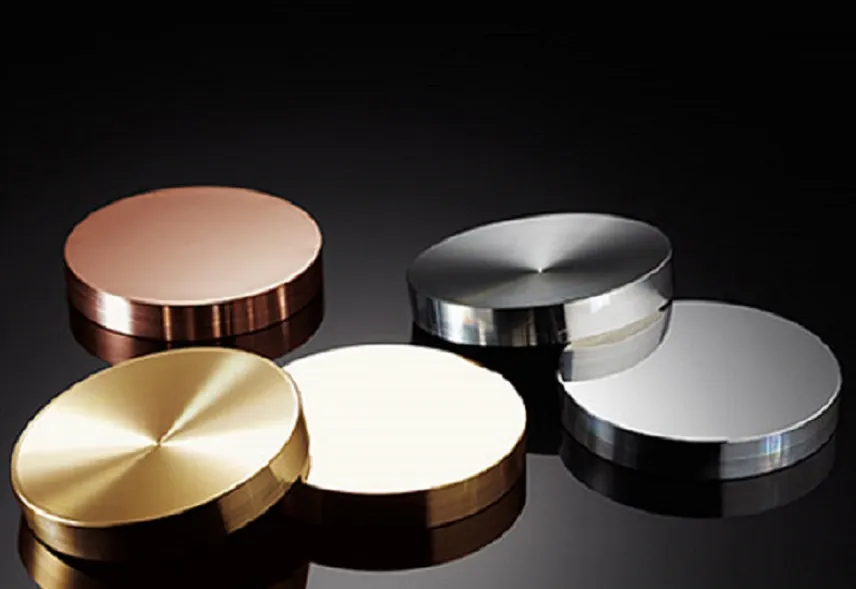

Sputtering Targets are high-purity materials used as the source in sputtering deposition processes to create thin films on substrates under vacuum conditions. These targets are manufactured with strict purity, density, and structural requirements to ensure consistent deposition rates, uniform film thickness, and high-quality coatings. Available in a wide range of metals, alloys, ceramics, and compound materials, sputtering targets are essential for advanced thin-film applications in research and industrial production. Ultrahivac supplies premium-quality sputtering targets suitable for PVD, magnetron sputtering, and advanced coating applications across industries in India.

Key Features & Benefits

High purity and density for consistent deposition

Uniform sputtering behaviour and film thickness

Available in metals, alloys, and ceramic materials

Compatible with magnetron and conventional sputtering systems

Suitable for research and industrial production use

Benefits

Reasons to Choose Our Sputtering Targets

Industries

Applications of Sputtering Targets

Information

How It Works and Technical Advantages

Target Installation

Plasma Generation

Ion Bombardment

Material Transport

Thin-Film Deposition

Continuous Deposition Control

FAQs for Sputtering Targets

They are used as source materials in sputtering-based thin-film deposition.

Metals, alloys, ceramics, oxides, nitrides, and compound materials.

Yes, purity and microstructure directly impact coating performance.

Yes, they are designed for continuous research and industrial use.

Yes, size, shape, bonding, and material composition can be customised.