Diffusion Pumping Stations – High-Vacuum Systems for Industrial, Research, and Coating Applications

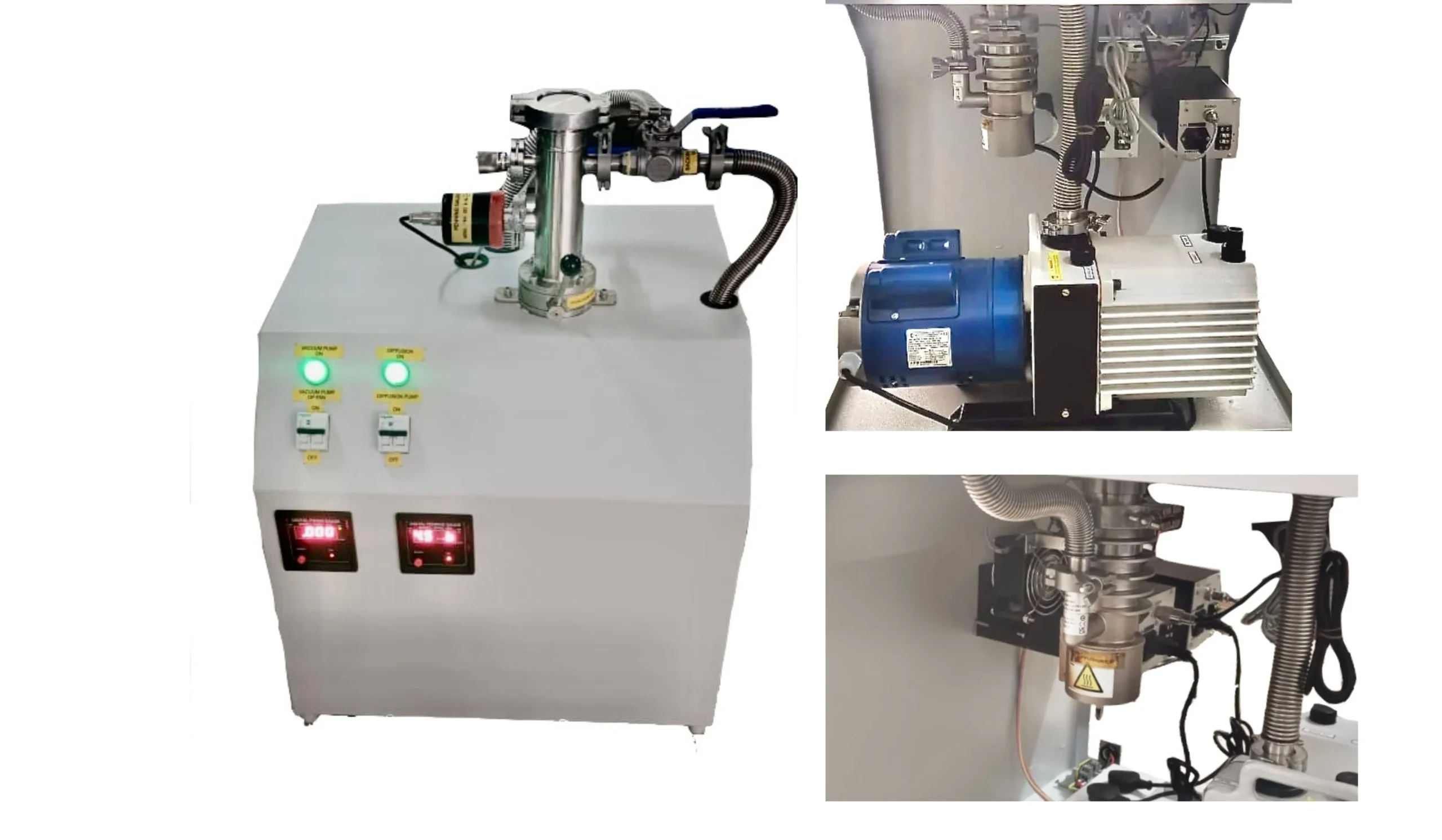

Diffusion Pumping Stations are integrated high-vacuum systems that combine a diffusion pump with a suitable backing pump, controls, cooling systems, and safety components to achieve deep vacuum levels reliably. Known for their rugged design, high pumping speed, and cost-effective operation, diffusion pumping stations are widely used in coating, metallurgy, research laboratories, and large industrial vacuum systems. Ultrahivac supplies engineered diffusion pumping stations designed for stable performance, long service life, and continuous operation across industrial applications in India.

Key Features & Benefits

Integrated diffusion pump and backing pump configuration

Capable of achieving high and very high vacuum levels

High pumping speed for large vacuum chambers

Robust construction with minimal moving parts

Cost-effective solution for high-vacuum requirements

Benefits

Reasons to Choose Our Diffusion Pumping Stations

Industries

Applications of Diffusion Pumping Stations

Information

How It Works and Technical Advantages

Backing Vacuum Generation

Vapour Jet Formation

Molecular Gas Transport

Vacuum Level Stabilisation

Thermal and Cooling Management

Continuous Industrial Operation

FAQs for Diffusion Pumping Stations

It is an integrated vacuum system combining a diffusion pump with a backing pump and controls.

It enables higher vacuum levels and better performance for large chambers.

Yes, they are designed for continuous industrial and research use.

They are widely used in coating, metallurgy, research laboratories, and manufacturing.

Yes, configurations are tailored based on vacuum level, chamber size, and application.