Why Vacuum Technology Is Everywhere (Even If You Don’t See It) ?

Most people never think about vacuum technology. There’s no reason to, until you realize that almost every advanced product around us depends on it.

From the smartphone in your hand to aircraft components, medical devices and research laboratories controlled vacuum environments quietly make modern industry possible.

At Ultrahivac, we work with teams who don’t just use vacuum systems they depend on them every day. This blog marks the beginning of our effort to explain vacuum technology in a way that is practical, clear, and grounded in real industrial experienc

So, What Exactly Is Vacuum Technology?

In simple terms, vacuum technology is about removing air and unwanted gases from a closed space to create a controlled environment.

But in industrial settings, it’s much more than that.

Vacuum allows engineers and scientists to:

Prevent contamination

Control reactions and processes

Achieve repeatable, reliable results

Different applications require different levels of vacuum:

Low vacuum for handling and packaging

Medium vacuum for industrial processing

High vacuum for electronics and coating

Ultra-high vacuum (UHV) for research, semiconductors and space simulation

Choosing the right level isn’t guesswork ,it’s a technical decision that directly affects outcomes.

How a Vacuum System Actually Works?

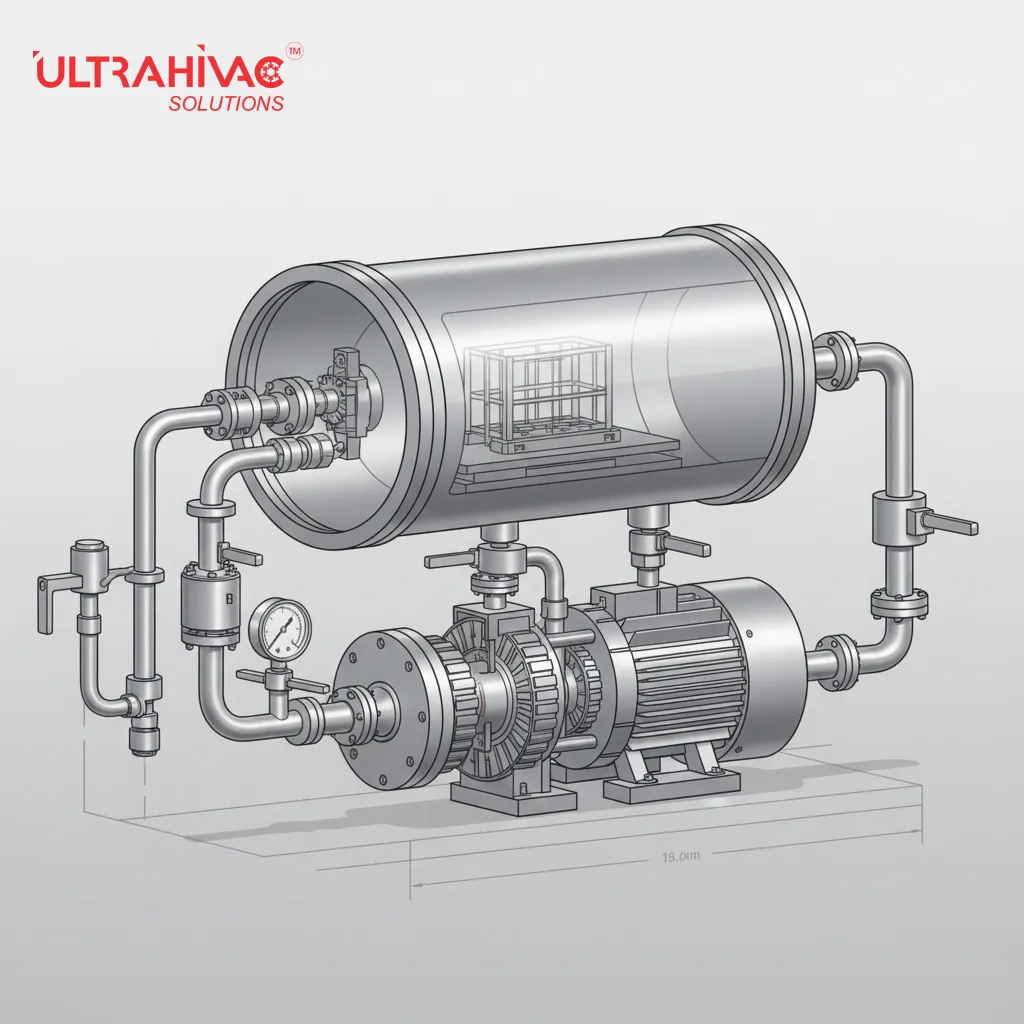

A vacuum system is not just a pump connected to a chamber.

It’s a combination of:

Pumps that remove gases

Valves that control flow

Gauges that measure pressure

Chambers and pipelines that hold the process

Leak detection systems that ensure stability

When everything works in harmony, the system runs quietly in the background.

When something is slightly off a seal, a fitting, a valve the entire process can suffer.

This is why system design and component compatibility matter as much as the pump itself.

Why Industries Rely So Heavily on Vacuum ?

Vacuum technology creates conditions that simply cannot exist at normal atmospheric pressure.

It enables:

Clean environments for sensitive materials

Accurate deposition and coating processes

Simulation of extreme conditions

Consistent manufacturing at scale

Industries such as semiconductors, aerospace, pharmaceuticals and advanced manufacturing are built around these controlled environments. Without vacuum, many of their core processes wouldn’t be possible.

Where Vacuum Technology Is Used Every Day ?

Vacuum systems are part of daily operations in:

Research and development laboratories

Semiconductor and electronics manufacturing

Aerospace component testing

Pharmaceutical drying and sterilization

Chemical and process industries

Coating, PVD, and CVD systems

Leak testing and quality assurance

Each use case has its own challenges and no two vacuum systems are truly identical.

Choosing the Right Vacuum Solution Is Not Just About Buying Equipment.

One of the most common mistakes we see is treating vacuum systems like standalone products.

In reality, selecting the right solution involves:

Understanding the process, not just the pressure

Matching materials to applications

Planning for maintenance and long-term reliability

The right system saves time, energy and cost. The wrong one creates downtime and frustration.

A Final Thought

Vacuum technology doesn’t demand attention but it deserves understanding.

This article is the first in a series where we’ll continue to break down vacuum concepts, applications, and real-world challenges in a way that engineers, operators, and decision-makers can relate to.

If vacuum plays a role in your process, this space is for you