Vacuum Pumping Stations – Integrated Vacuum Solutions for Industrial and Process Applications

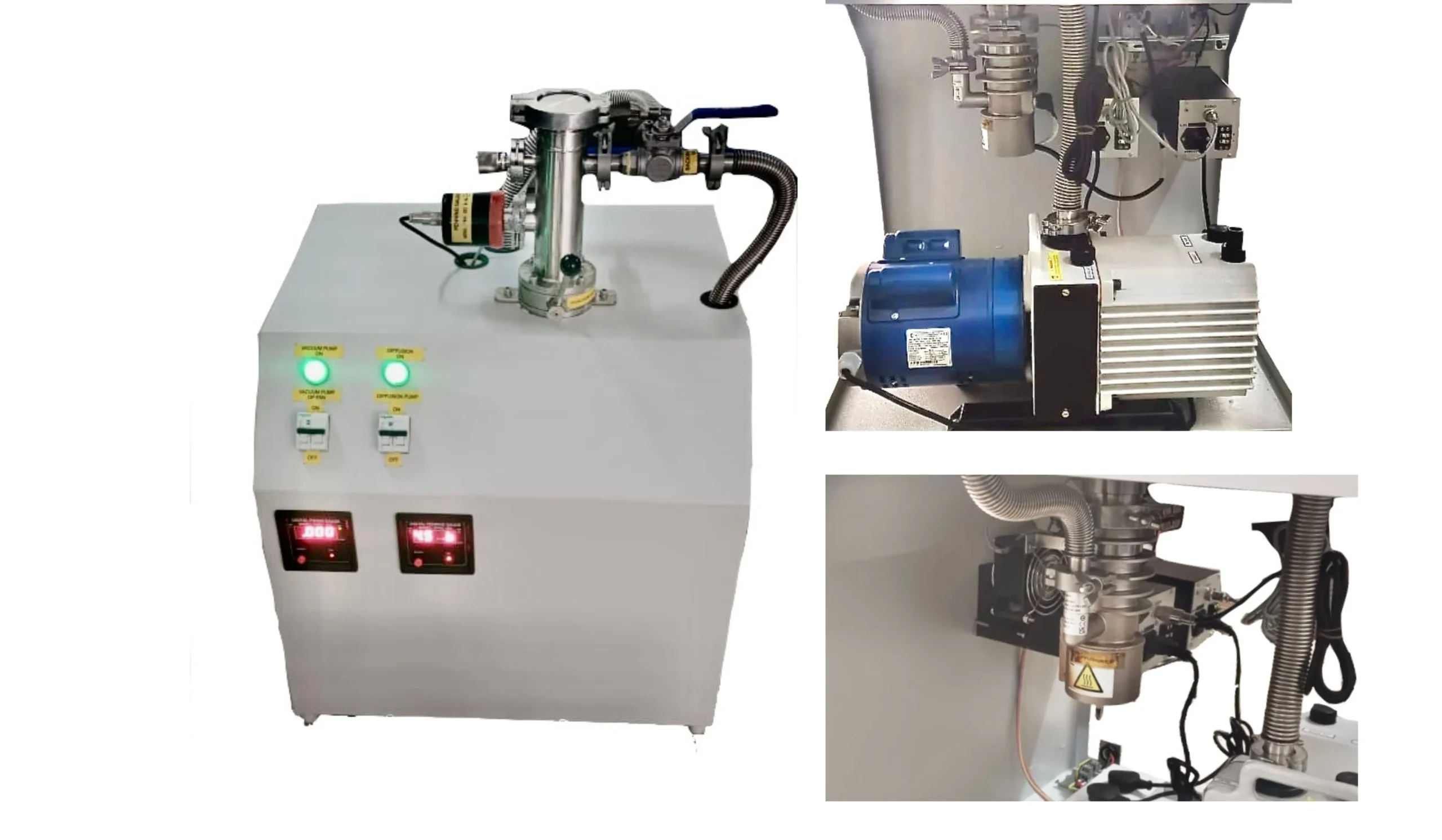

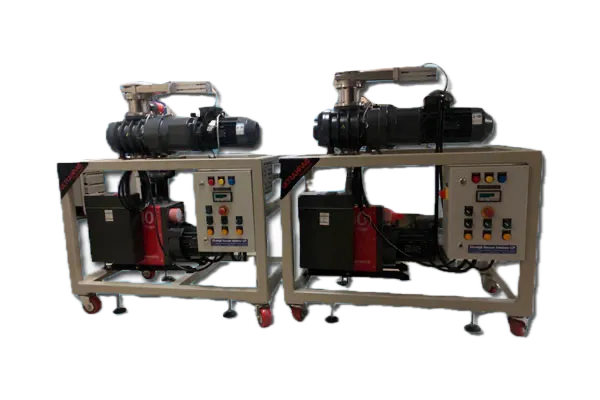

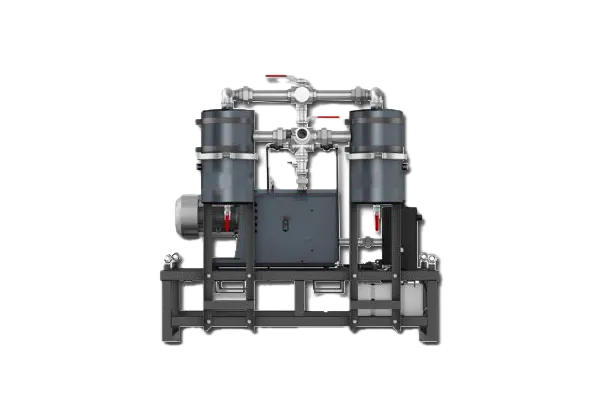

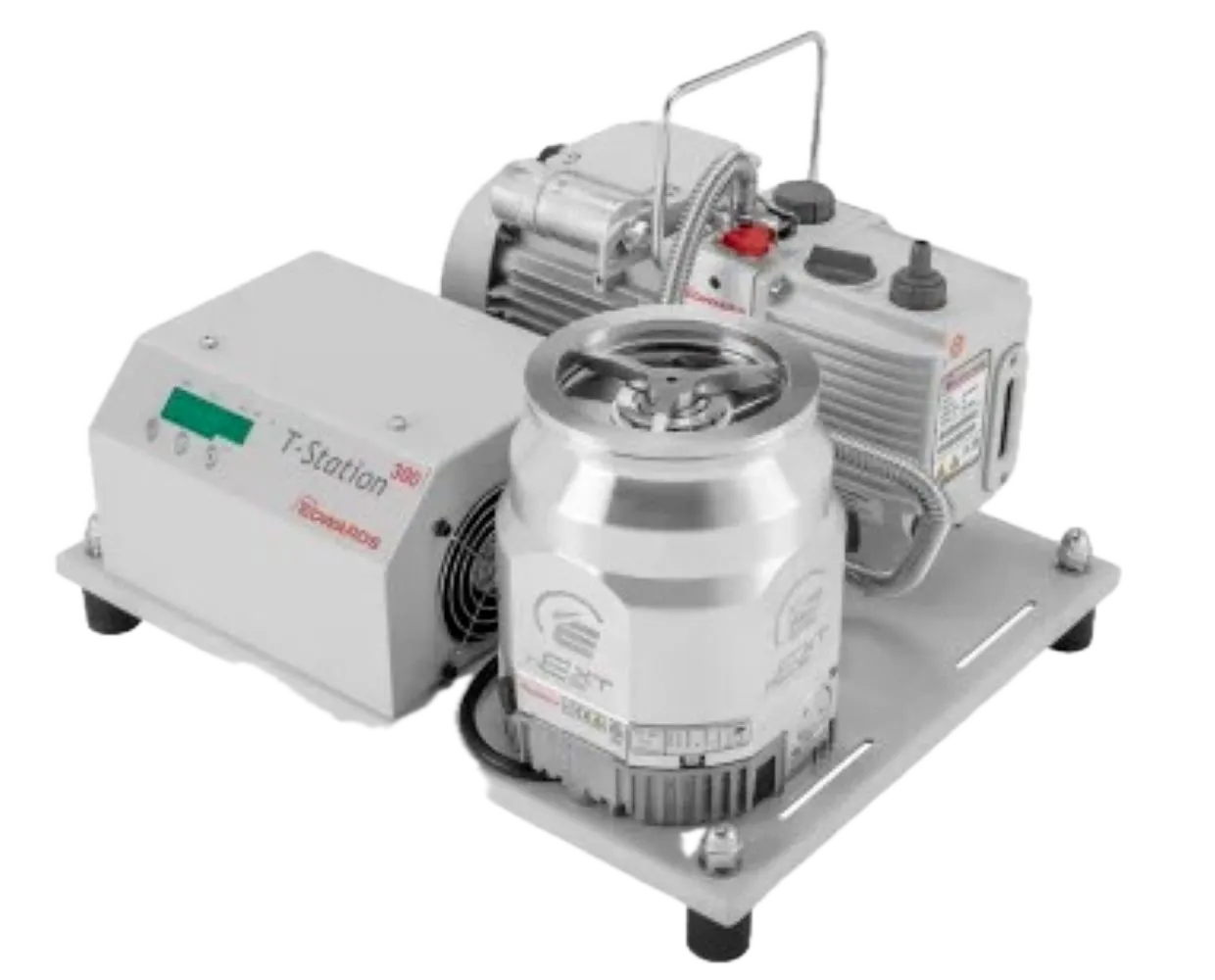

Vacuum Pumping Stations are complete, engineered vacuum systems that combine one or more vacuum pumps with control units, piping, valves, and safety components on a single skid or frame. These systems are designed to deliver reliable, efficient, and application-specific vacuum performance for industrial, scientific, and manufacturing processes. Vacuum pumping stations offer improved system stability, simplified installation, and optimised performance compared to standalone pumps. Ultrahivac supplies customised vacuum pumping stations designed for continuous operation across diverse industries in India.

Key Features & Benefits

Fully integrated vacuum systems with pumps, controls, and accessories

Custom-designed configurations based on application requirements

Improved vacuum stability and system efficiency

Reduced installation time and simplified commissioning

Suitable for continuous and heavy-duty industrial operation

Products

Available Types of Vacuum Pumping Stations

Benefits

Reasons To Choose Our Vacuum Pumping Stations

Industries

Applications of Vacuum Pumping Stations

Information

How It Works and Technical Advantages

Vacuum Generation

Compression Principle

Gas Transfer Path

Vacuum Stability Control

Thermal and Mechanical Protection

Continuous Operation Capability

FAQs for Vacuum Pumping Station

It is an integrated vacuum system that combines pumps, controls, and accessories into one unit.

Integrated systems offer better stability, higher efficiency, and simplified installation.

Yes, they can be configured based on vacuum level, pumping speed, and application needs.

They are widely used in semiconductors, chemicals, pharmaceuticals, aerospace, and manufacturing.

Yes, they are designed for continuous industrial duty cycles.